Want to save on your power consumption?

Get the solution NOW! It just takes a call to reach us!

Corporate Office

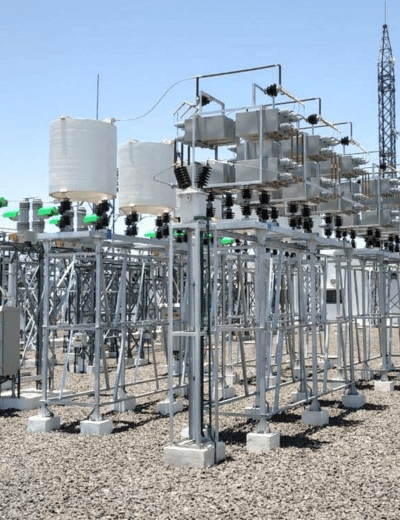

Our State of Art Manufacturing Facility of 1,00,000 sq. ft. area

Clariant Power System Ltd. is a leading Indian engineering company specializing in Power Quality, Reactive Power Compensation, Grid Stability, and Energy Efficiency Solutions.

With more than 25 years of industry leadership, we deliver advanced technologies that improve the reliability, efficiency, and safety of electrical networks across industries, utilities, and renewable energy plants.

Founded in 1998, Clariant Power has grown into a trusted partner for reactive power management, harmonic mitigation, STATCOM/SVG systems, APFC panels, series reactors, and turnkey PQ solutions. Our solutions support India’s rapidly expanding transmission, distribution, and renewable energy sectors.

We have delivered more than 4.5 GVAR of reactive power solutions and completed large-scale projects for solar parks, wind farms, data centres, heavy industries, SEBs, railways, and international clients across the Middle East, Africa, and Southeast Asia.

Backed by a state-of-the-art manufacturing facility in Pune, certified by ISO 9001, ISO 14001, ISO 45001, and supported by CPRI/ERDA-tested products, we ensure global-standard quality and reliability in every project. Our long-standing technical associations with Frako (Germany) and FGI (China) enable us to embed world-class engineering into our solutions.

Today, Clariant Power stands at the forefront of India’s Power Quality transformation, working closely with utilities, grid operators, renewable developers, EPC companies, and industrial leaders to enable a more stable and efficient electrical ecosystem.

Clariant Power System Ltd. Capacitors is a privately owned company operating in the global market through a powerful sales and distribution network. We offer solutions to save energy and to improve power quality by reactive power compensation and harmonic filtering. Some of our key achievements include:

To be a ‘powerful’ name and a respected and valued brand, which is the preferred choice for our customers for excellent holistic power solutions resulting in saved energy, money and improved power system performance.

Keeping the price most reasonable and affordable, we seek to offer excellence in quality products, solutions, systems, and services in the field of Power Quality and Reactive Power. Ensure a value-for-money customized power solution for customers across various industry segments, while committing to inspire, educate and prepare them to implement quality power solutions by choice, and not merely to comply with regulations.

Get the solution NOW! It just takes a call to reach us!

It gives us immense pleasure to share the milestones that we have set in Power Quality Management by achieving Current & Voltage Harmonics much lower than the levels specified by TANGENCO / CEA.

At Hinduja Foundries, Chennai (East Land), we successfully reduced A(THD) from 15.40% to 6.50% & V(THD) from 4.80% to 2.50% by installing Specially Designed Tapped Tuned Harmonic Filters. This resulted in several benefits, some of which include improvement in Power Factor to Unity from 0.94, reduction in Individual Current & Voltage Harmonic level to 1%, reduction in almost 5.05% KVA at full load condition, reduction in RMS Current which is 6.2% at 33 KV, and savings in terms of Units consumption resulting in direct benefit with respect to the electricity bill.

At ABI Showatech (India Ltd), Chennai (TVS Group), we reduced A (THD) from 14.5% to 3.1% & V(THD) from 3.1% to 1% by commissioning the Tuned Contactor Switched AHPFC panel. A(THD) & V(THD) levels at ABI Main Incomer are now well within Limits as per CEA Guidelines.

After successful installation of 350 KVAR, 525V Tuned Automatic Harmonic filters on 23.11.14 by Clariant Team ATHD levels were reduced to 5.20 % from 16.2% at SS 1 Location and 2.88% to from 22.2 % at SS 2 Location respectively.

We have bagged a prestigious Purchase Order from M/s Daelim – Petrofac SRIP Joint Venture. (A joint Venture of Daelim Industrial Co. Ltd and Petrofac International Limited) for Sohar Refinery Improvement Project. The size of the installation is approximately 30 MVAR Capacitors at 36 KV with all associated controls, Switchgear, and Harmonic Filters at one location. We have received prestigious purchase orders from Larsen & Tuobro Ltd. Hydrocarbon Abu Dhabi for New Abu Dhabi International Airport Aviation Fuel Depot Project.

We also received major purchase order from Watania Steel & NAJD Steel, Riyadh, Saudi Arabia. We got major breakthrough in the tyre segment & executed overseas project in Thailand & Indonesia for GoodYear Tyres and achieved the best promise result as per contract.