Thermography

Thermography is a nondestructive test method that may be used to detect poor connections, unbalanced loads, deteriorated insulation, or other potential problems in energized electrical components.

These problems may lead to excess power use, increased maintenance costs, or catastrophic equipment failure resulting in unscheduled service interruptions, equipment damage, or other problems.

How Does Thermography Work?

Thermography, also called infrared inspection, is based upon the sensing of heat emitted from the surface of an object in the form of infrared radiation. Test instruments are used to detect and convert the infrared radiation into either a temperature value or a thermal image, which can be used to assess the thermal condition of the object at the time of measurement. An infrared camera is one common type of an infrared thermal imaging device.

It shows a visual picture so temperatures over a large area can be compared.

It is capable of catching moving targets in real time.

It is able to find deteriorating, i.e., higher temperature components prior to their failure.

It can be used to detect objects in dark areas.

It is a non-destructive test method.

It can be used to measure or observe in areas inaccessible or hazardous for other methods.

How Can Thermography Be Used to Inspect Electrical Equipment?

Energised electrical systems generate heat because of electrical resistance. The amount of heat generated is related to the amount of current flowing through the system and the resistance of the individual system components and connections within the system. As components deteriorate, their resistance increases, causing a localised increase in heat. Similarly, a poorly made connection will have higher resistance than a well-made connection generates excess amount of heat which will lead to the failure of the equipment. Thermography may be used to detect these hot spots and repair them efficiently.

Upgrade your Power Systems!

We have always made sure to put quality over profits and will always provide you with the best of products in the market. Contact us to optimise your energy consumption.

More Products

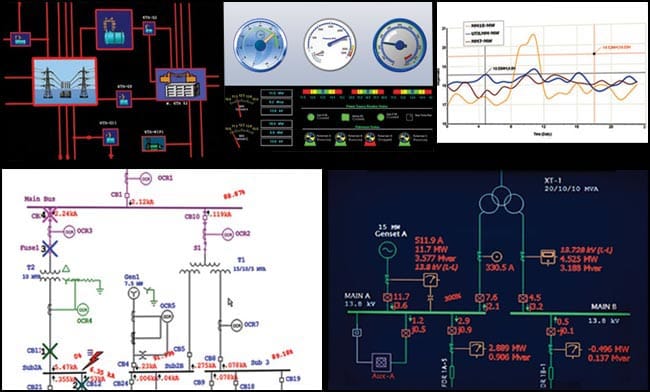

Our product portfolio comprises of a comprehensive collection of the systems including:

(STATCOM/SVG) Static Compensator

STATCOM is a Step less Variable Source of Reactive Power that can provide both Capacitive and Inductive power.

Contactor Switched Automatic Harmonic Filter Panel (AHPFC)

AHPFC Panel is centralized reactive power compensation with harmonic mitigation.

Thyristor Switched Automatic Harmonic Filter Panel (RTPFC)

RTPFC Panels are ideal for eliminating power factor problems in real time for large systems with fluctuating loads.

Active Harmonic Filters

(AHF)

Active Harmonic Filters (AHF) today is designed to calculate the amplitude and phase angle of each harmonic order up to 71st Order Harmonics.

Static VAR Generators (SVG/SVG+)

Clariant Power System Limited’s Static VAR Generator (SVG) is a Step-less Solutions to improve Power Factor.

Hybrid Reactive Power Compensation

Hybrid Broadband Passive Filters (HBPF) is a combination of series and shunt broadband filters.

MV Fixed/Automatic PF Improvement Capacitor Bank (Indoor Type)

With advanced methodology, Clariant Power System Limited design and manufacture customized Power Factor Correction Systems for Medium Voltage & High Voltage applications

Surge Protection Capacitors (SPC)

Surge capacitors work by absorbing the energy from electrical surges, providing protection to the equipment.

Get in Touch

- Contact US

Have a project in mind? Contact with us

We’d love to share more with you, please complete this form and our dedicated team will get back to you shortly.

Address Company

799/A, Clariant House, Abhijeet Court, Bhandarkar Road, Pune-411004.

Phone: +91 9130057668 , 020-67332999

Email: sales@clariantindia.co.in